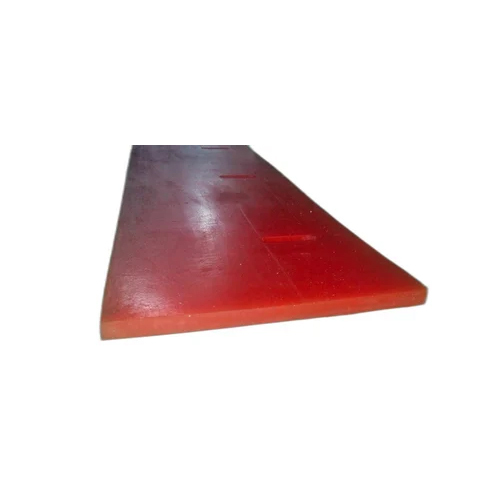

Polyurethane Chute Liner

Price 1200 INR/ Kilograms

Polyurethane Chute Liner Specification

- Classification

- Other

- Type

- Plastics

- Grade

- Industrial Grade

- Purity

- 98% 99% 100%

- Application

- Other

- Color

- Multicolored

- Form

- Solid

- Material

- Polyurethane

Polyurethane Chute Liner Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO9001:2015 CERTIFIED COMPANY

About Polyurethane Chute Liner

Polyurethane Chute Liner is a specialized protective lining used in various industrial applications to prevent wear, abrasion, and damage to chutes and other material handling equipment. It is made from high-quality polyurethane, a versatile polymer known for its durability, flexibility, and excellent wear resistance. Polyurethane Chute Liner is designed to be installed on the interior surface of chutes, hoppers, and other material handling systems where materials such as ores, minerals, aggregates, coal, and other abrasive or bulk materials are transported.

Why Choose Polyurethane Chute Liners?

Polyurethane Chute Liners offer superior performance over traditional materials like metal and rubber. Due to their high purity, industrial-grade formulation, and solid construction, they provide excellent resistance to wear, impact, and chemicals. These liners also help in noise reduction and are suitable for a variety of industries such as mining, cement, and bulk material handling.

Versatile Applications in Industry

Our polyurethane liners are suitable for use across multiple sectors, including mining, minerals, agriculture, and power plants. Their versatility stems from their multicolored, high-purity options and robust physical properties, making them the preferred choice for protecting chutes, hoppers, and material transfer points from premature damage and ensuring operational continuity.

FAQs of Polyurethane Chute Liner:

Q: How are Polyurethane Chute Liners installed in industrial settings?

A: Polyurethane Chute Liners are typically installed by bolting or bonding them to the inner surfaces of chutes, hoppers, or bins. Depending on the application, standard or custom-sized liners can be provided for an easy installation process and secure fit.Q: What are the benefits of using high-purity (98%100%) Polyurethane Chute Liners?

A: High-purity polyurethane liners offer enhanced resistance to abrasion, impact, and chemicals, extending equipment lifespan. They also reduce maintenance frequency and downtime, improving overall efficiency in material handling environments.Q: When should I consider replacing my existing chute liner with a polyurethane option?

A: You should consider switching to polyurethane liners when your current liners show significant wear, frequent failures, or are not providing adequate protection against abrasion. Polyurethane liners are ideal for applications requiring improved durability and cost-effectiveness.Q: Where can Polyurethane Chute Liners be used?

A: These liners can be used in chutes, hoppers, bins, and material transfer points in industries like mining, cement manufacturing, steel, power generation, and agriculture to protect against wear and impact.Q: What is the process of ordering custom-sized Polyurethane Chute Liners from India?

A: To order custom-sized liners, provide your chute specifications and operational requirements. Our team will assist in selecting the appropriate grade and color, followed by manufacturing and delivery tailored to your projects needs.Q: How does the multicolored feature of these chute liners benefit users?

A: Multicolored liners can help identify wear zones more readily and facilitate organization within material handling systems. Different colors may also assist in tracking liner usage or product flow for safety and maintenance purposes.Q: What support does your company provide as a distributor, exporter, and manufacturer in India?

A: We offer full consultation, product customization, prompt delivery, and after-sales support. Our experienced team assists with technical queries, ensures compliance with industry standards, and delivers globally as both a supplier and service provider.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Mining Products Category

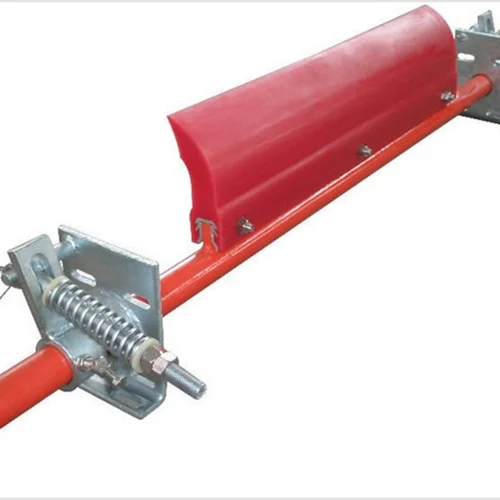

Internal Belt Cleaners

Price 13000 INR / Set

Minimum Order Quantity : 10 Sets

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : Polyurethane

PU Wiper Blade

Price 1100 INR / Piece

Minimum Order Quantity : 50 Pieces

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : Polyurethane

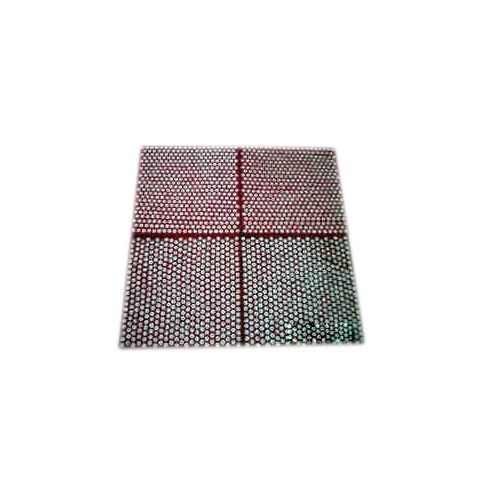

Rubber Ceramic Liner

Price 2500 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : Rubber

Poly Urethane Hydrocyclone

Price 60000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Multicolored

Form : Solid

Grade : Industrial Grade

Material : Polyurethane

|

SWAGATH URETHANE PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry